This article, written by Hi Sibley, was published in the Sept. 1947 issue of Mechanix Illustrated. Even though this is clearly a teardrop camper, the word teardrop does not appear in the article, nor does the terms RV or recreational vehicle. Images and figures have been enhanced. Click on any for larger versions

A streamlined home on wheels that’s light and easily towed; has a double-berth and complete kitchenette.

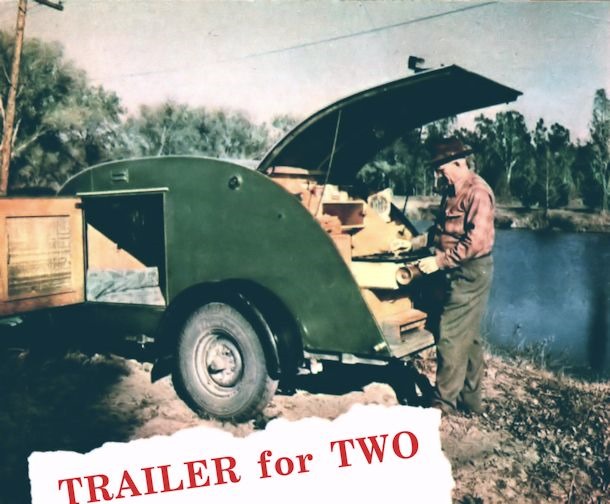

Original trailer designed by Howard Warren of Riverside, Calif. has travelled thousands of miles

“Getting away from it all” doesn’t mean giving up the comforts of home, for with this compact trailer you bring them right along with you. As it’s only a fraction of the size and weight of a full-grown trailer, you can take this 10-ft. tourer wherever a car will go. And when you reach some ideal spot between a lake or stream, up goes the kithenette and in a matter of minutes there’s an appetizing meal cooking away on the pull-out stove. Under the same hood, there’s an icebox (for the big ones that didn’t get away), a water tank, folding table and cupboard space for a raft of food. After you’ve finished tucking away your share of it for dinner, you can open one of the doors and there’s a full-length mattress waiting

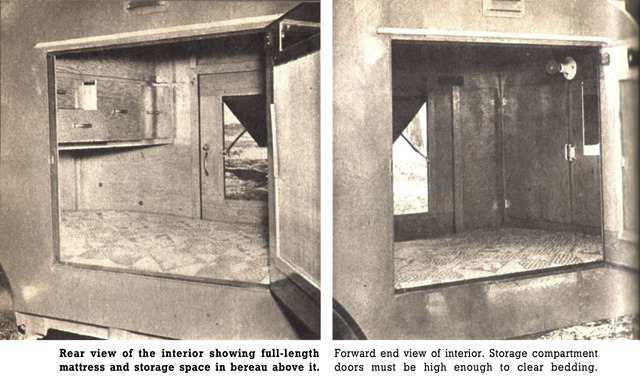

“Getting away from it all” doesn’t mean giving up the comforts of home, for with this compact trailer you bring them right along with you. As it’s only a fraction of the size and weight of a full-grown trailer, you can take this 10-ft. tourer wherever a car will go. And when you reach some ideal spot between a lake or stream, up goes the kithenette and in a matter of minutes there’s an appetizing meal cooking away on the pull-out stove. Under the same hood, there’s an icebox (for the big ones that didn’t get away), a water tank, folding table and cupboard space for a raft of food. After you’ve finished tucking away your share of it for dinner, you can open one of the doors and there’s a full-length mattress waiting for you when you turn in. And if you like fresh air when you sleep, just open the screened-in panels on the doors.

for you when you turn in. And if you like fresh air when you sleep, just open the screened-in panels on the doors.

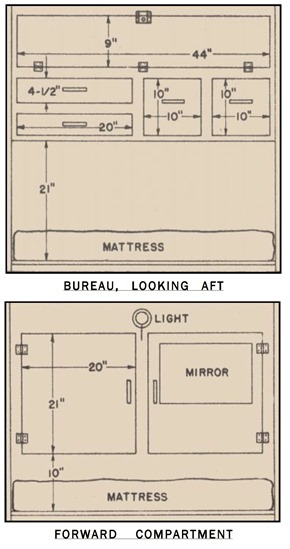

The interior of the trailer has good sitting room and a bureau with plenty of storage space for clothes. There’s even an electric light for reading in bed.

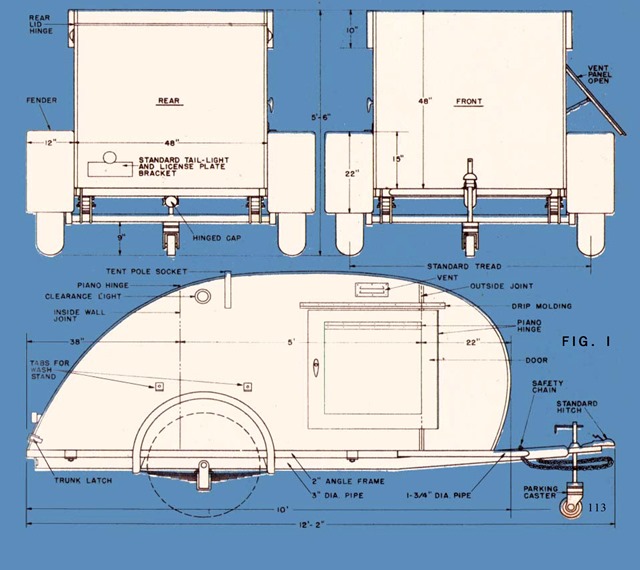

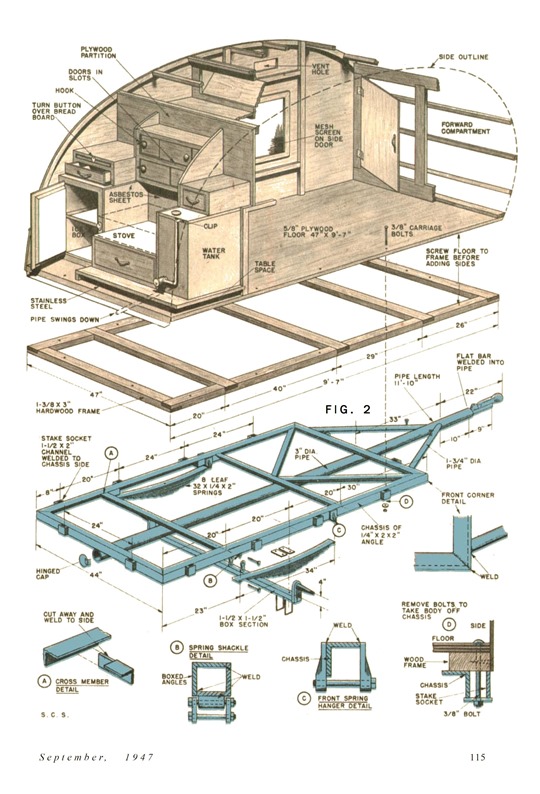

Now let’s take a look at the drawings on these pages & then get on with the actual construction. The trailer has a welded angle-iron chassis that’s illustrated in Fig. 2. This doesn’t extend the full length of the body so that you can remove the camp body & substitute an open box type. If this might give your wife ideas about building a rock garden, then make the chassis the full length of the body & play safe.

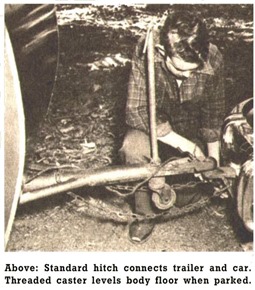

The chassis should be built up of 1/4″ by 2″ by 2″ angle iron, mitered & welded at the corners & with cross members welded to the side frames. Be sure & grind off all the rough spots. If you’re going to use it for pleasure alone, you can use a little lighter stock & save on the weight. At the locations indicated, weld the forward spring hangers to the side frames & the rear spring shackle brackets to boxed sections of the frame. The tow bar extends the full length of the frame & should be welded to the cross members, with the forward end canted up slightly by bending the pipe as shown in Fig. 1. A standard hitch should also be welded at the front end. Incidentally, that hinged cap at the back end of the pipe is a stunt of Mr. Warren’s for stowing his fishing rods inside it.

The chassis should be built up of 1/4″ by 2″ by 2″ angle iron, mitered & welded at the corners & with cross members welded to the side frames. Be sure & grind off all the rough spots. If you’re going to use it for pleasure alone, you can use a little lighter stock & save on the weight. At the locations indicated, weld the forward spring hangers to the side frames & the rear spring shackle brackets to boxed sections of the frame. The tow bar extends the full length of the frame & should be welded to the cross members, with the forward end canted up slightly by bending the pipe as shown in Fig. 1. A standard hitch should also be welded at the front end. Incidentally, that hinged cap at the back end of the pipe is a stunt of Mr. Warren’s for stowing his fishing rods inside it.

The stake pockets indicated on Fig. 2 can be omitted if your not going to use the chassis for hauling. Two standard 34″ springs with a welded box-section axle fastened to them with U-bolts, support the chassis & absorb road shocks. All in all, the construction is a bit heavier than you’d normally require for a camp trailer alone but it will really take a gaff.

The next operation on the program is to make the simple hardwood frame which is bolted to the side and end members (also the stake pockets, if you’re using them) of the chassis. The front end of the frame is bolted to the diagonal pipe braces. Next, cut the floor from 5/8 in. plywood, and glue and screw it to the frame. Drill holes through the assembly & bolt it down to the chassis shown in Fig. 2.

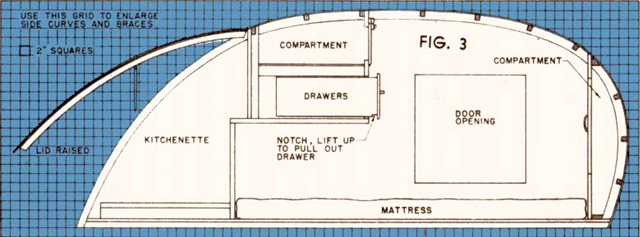

Your next chore is to make the sides of the body, using 1/4″ plywood panels covered with the same thickness of Masonite. Lay the ladder face down on a level floor, spread the glue and drop the plywood on top. Then spread a dropcloth or tarpaulin over the “sandwich” & cover it with dry sand to press the layers together. If you can’t get 12′ panels, you’ll have to make a joint near the front edge of the door (see Fig. 1). When the glue is dry, cut the sides to shape, following the dimensions in Fig. 1 & the pattern in Fig. 3 & then cut the openings for the doors & vents. Use the same grid to bandsaw the 1/4 in. by 2″ plywood braces to shape. After these are glued & screwed to the sides (from the inside), cut notches through the braces & the plywood (but not through the Masonite covering) for the 1 by 1 1/4″ beams which support the top.

You’re now ready to assemble the sides to the floor, fastening them along the bottom with screws into the frame. Then cut the beams to the correct length and glue them in place, using a wood screw at each notch. Cut the framing for the forward and rear partitions from 5/8″ plywood, with openings in the forward one for the doors leading to the front compartment, and install the partitions. Figs. 2 & 3 will give you the location & details of these. Next, add the framing for the compartment & drawers, including slides, of the bureau.

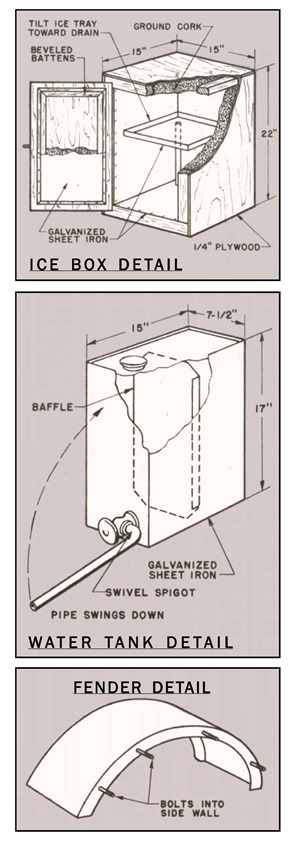

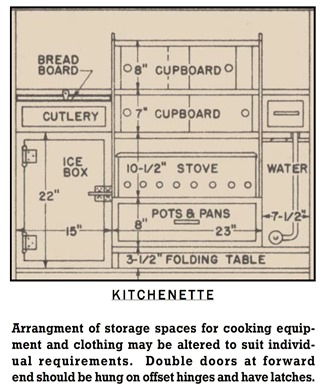

The kitchenette comes next, and here the arrangment will depend on the equipment that you plan to use. If you’re using the usual two-burner camp stove, you can follow most of the dimensions and details in Fig. 2 and the detailed drawing of the kitchenette on page 117. Make the ice box and water tank first, following the detailed drawings for these, and install them in place. The tank rests on a shelf with space beneath it for a regular-sized bridge table for chow time. When these units are in place, add the framing for the utensil compartment, the top of which forms a base for the stove. Don’t forget to line this space (and under the cupboards too) with sheet asbestos to reflect the heat. The framing for the cupboards, bread slide and cutlery drawers should then be fitted in place. Make all the cupboard & compartment doors, bread slide, bureau and kitchenette drawers, etc. at one time and don’t forget to notch the latter so they won’t tumble out & strew your wife’s underwear or the knives & forks all over the place. The cupboard doors, made of 1/4″ Masonite, sliding in rabbets, should have small hooks to keep them closed. When you’re finished with all the cabinet work, the body should look like the drawing in Fig. 2. Then, while you still have room to work inside, add the wiring for the clearance lights which will connect to the regular car lighting circuit. The interior lights, one over the front compartment doors & the other on the rear lid, are wired later & connected to a separate battery.

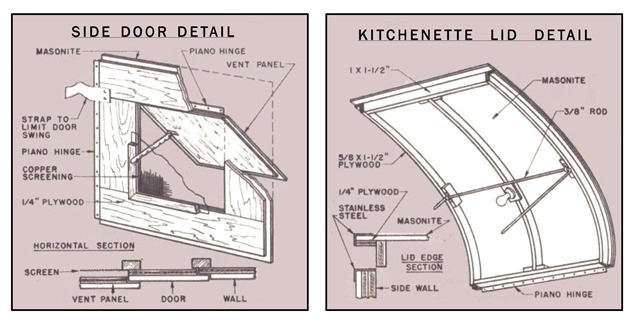

The 1/4″ Masonite top can now be glued & screwed to the side braces & beams, using a stainless steel angle moulding to cover the seams at the sides. The kitchenette lid is then made, following the details in the small drawings & the pattern in Fig. 3. The lid is hung from the top with a long piano hinge & a 3/8″ rod installed as shown in the drawing to hold it up.

The 1/4″ Masonite top can now be glued & screwed to the side braces & beams, using a stainless steel angle moulding to cover the seams at the sides. The kitchenette lid is then made, following the details in the small drawings & the pattern in Fig. 3. The lid is hung from the top with a long piano hinge & a 3/8″ rod installed as shown in the drawing to hold it up.

You’re on the home stretch now & the next job is to make the side doors. These are hung from the sides so that when closed they’ll be flush with the outside walls. A regular car door handle & a simple bar lock inside, complete the hardware on them. You can now paint the outside of the trailer and varnish the interior. Make the fenders from heavy sheet metal & bolt them to the side walls.